Mig welders do fly

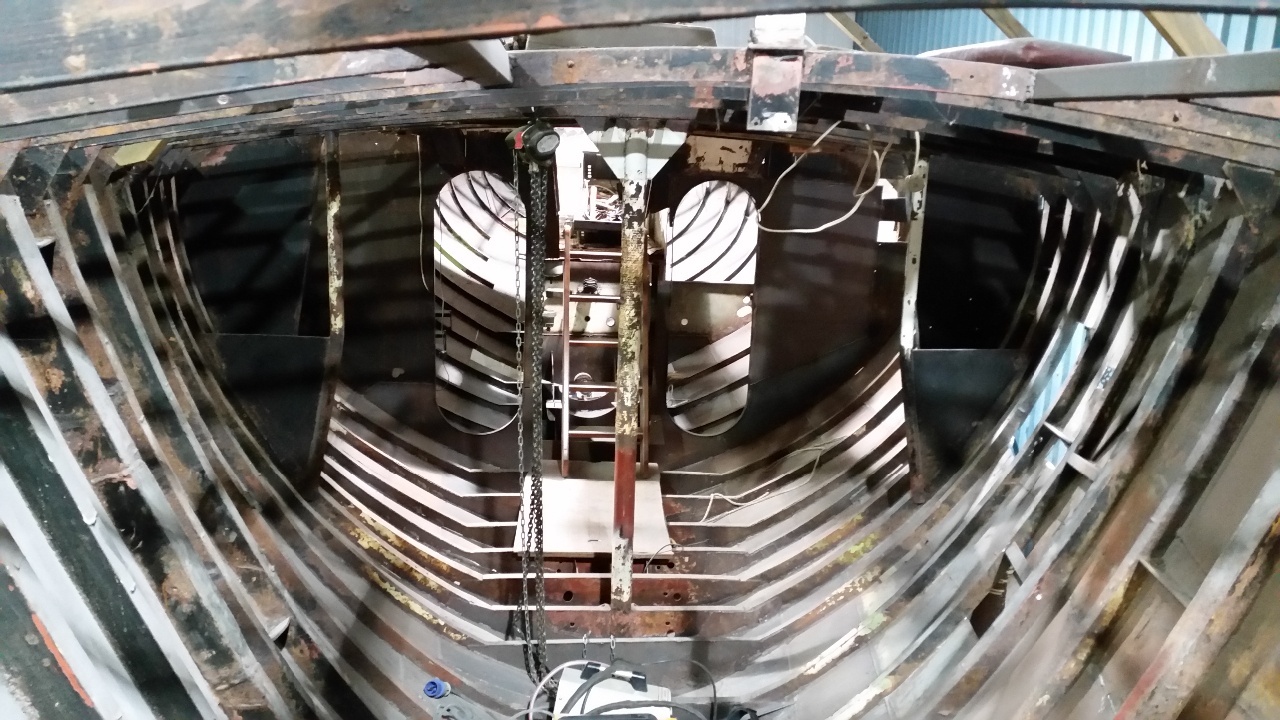

High up work is always a challenge. It's just as difficult inside the hull as there is nothing to wedge yourself up against whilst welding. I have also decided that seam welding on both sides is best. Although they say that both sides is only necessary below the waterline.

Some parts of the hull is faired with upto 10mm of fairing filler.

Since this photograph was taken the rusty topsides have been sanded down.

The very top edge between the hull and the deck (gunwhale) has had the fairing filler removed in readiness for decks to be welded to the hull.